Redex USA objectives remain the same: Providing quality unique gearboxes and solutions for use on industrial machinery.

All Sales, Engineering, Manufacturing and after market support are located at our headquarters in Wanamassa, New Jersey.

Each member of our sales and engineering teams offer our customers the technical expertise required to meet their application requirements, custom designs, support and solutions to enhance productivity.

As part of the global network of companies and products sold under the Redex-Andantex brand name, and in conjunction with world class rack manufactures, Redex USA is recognized as a leading provider of high-precision motion control components and systems.

Redex Product Line

Servo Reducers | Mini Servo Reducer | Servo Worm Reducer | Rack & Pinion Systems and Components | 2 Speed Spindle Gearboxes

Automatic Lubrication System | Lifting Systems | Made to Order Large Gears | Right Angle Gearboxes | Differentials | Mechanical Clutches

Reducers & Multipliers | Magnetic Particle Brakes, Clutches & Torque Limiters | Electronics & Controllers | Transducers & Limiters | After Market

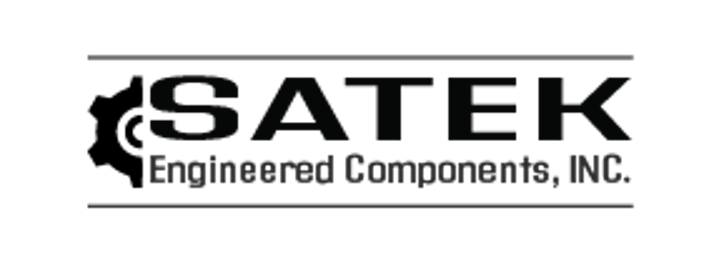

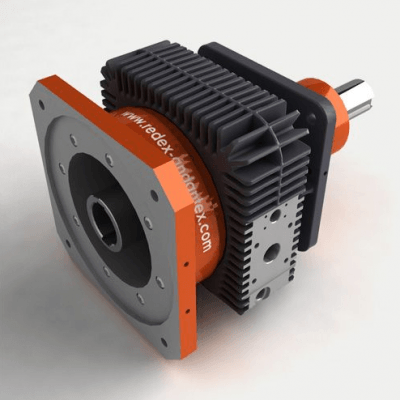

Servo Reducers - Planetary

Redex offers four families of planetary reducers optimized for stiffness & precision. DRP, KRP and KRPX reducers are dedicated to rack & pinion or pinion ring gear drives with radial and torsionally rigid integral output pinions. SRP is a versatile unit that can be integrated with split pinions, ballscrews, couplings or pinions. ZERO-BACKLASH is achieved using DualDRIVE (mechanical preload) or TwinDRIVE (electrical preload). Over 3000 configurations possible offering the perfect balance of performance & price.

Mini Servo Reducers - Planetary

Due to their outstanding properties, planetary gearboxes are used in all kind of industrial applications. Güdel high precision planetary gearboxes ideally cover demanding requirements. With regard to angular backlash, our long experience in the conception and the manufacturing of high-performance gearboxes gives us the ability to provide all products in four different precision classes.

Servo Worm Reducers

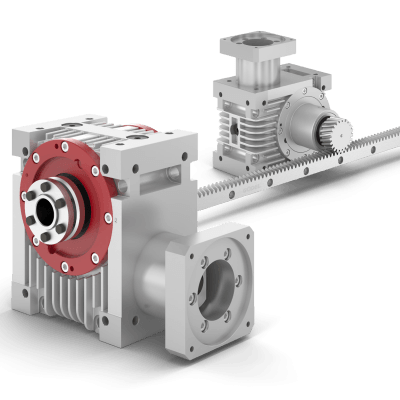

Redex USA Inc. offers a full range of modular servo gearboxes /worm reducers. The modular design allows for configurations with motor input flange and output pinion for rack and pinion drives, as well as solid output shafts, Hollow bore output, and input shafts for all other positioning applications. The modular design allows for universal mounting of the gearbox in any orientation.

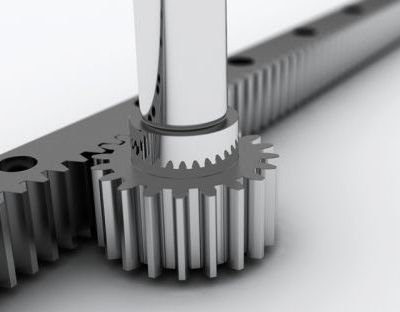

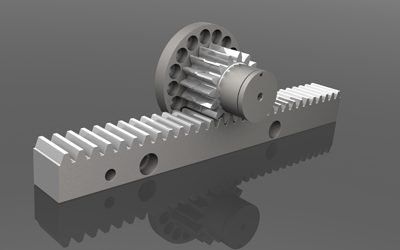

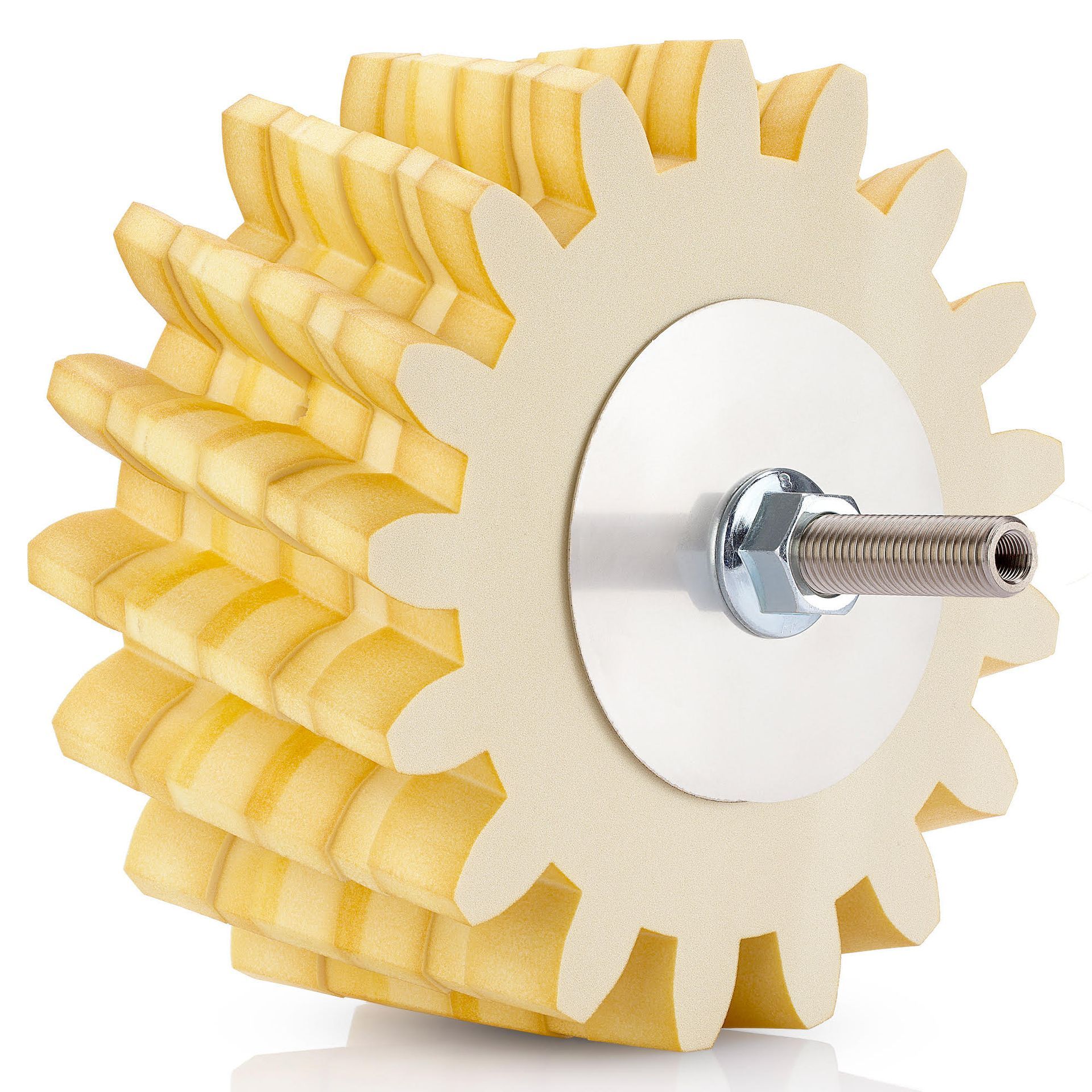

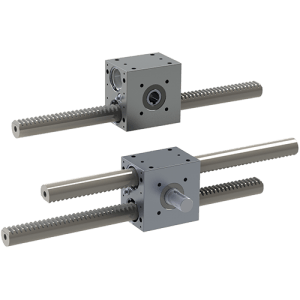

Rack and Pinion Systems & Components

A complete range of standard rack and pinion components for all linear motion requirements, from ultra-high precision to brute force applications.

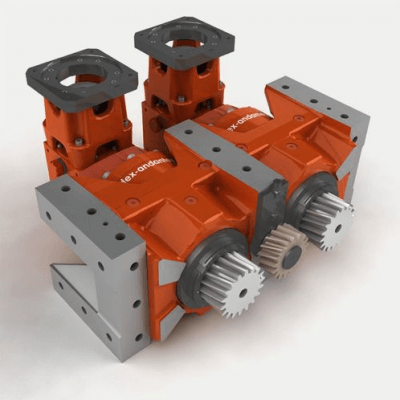

2 Speed Spindle Gearboxes

The 2 Speed Gearbox family of products offers the perfect balance of speed performance and price. They extend the constant power speed range of machine tool spindle drive motors, providing high torque at low speed for hogging out steel or titanium, and high speed for finishing aluminum.

Automatic Lubrication System

Specialized lubrication pumps with accessories and specialty greases for automatic re-lubrication of racks and pinions, open gearing, linear guideways, ball screws, and chain drives.

Lifting Systems

The Rack Jack from WMH Herion provides simple synchronous lifting motion. The system of rack and pinion transforms linear motion to rotation and vice versa.

Made to Order Large Gears

Complex gearing parts are often required for customized applications. Andantex’s partner WMH Herion has been developing and manufacturing customized gearing solutions for more than 120 years. From design to ready-to-install drive elements we support you in all phases of product development. Our manufacturing capabilities include ring gears, gear segments, spiral bevel gears, right angle gearbox, 2 speed gearboxes bevel gears, herringbone gears, chain sprockets and plate wheels.

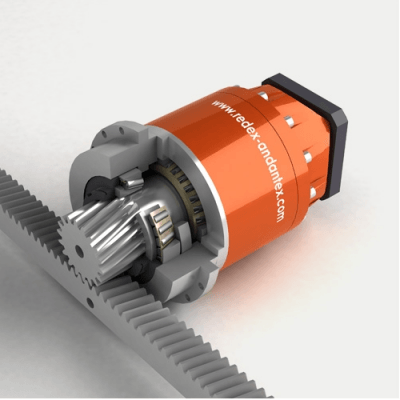

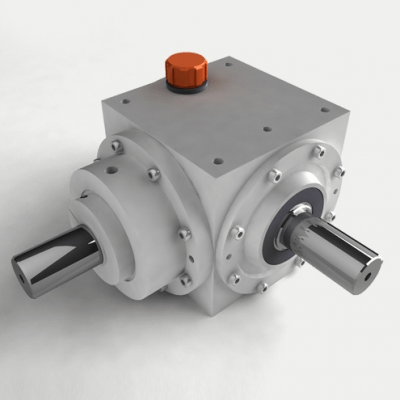

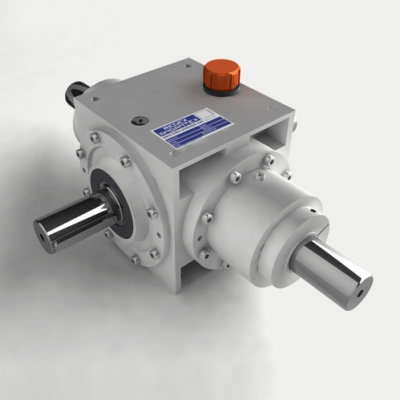

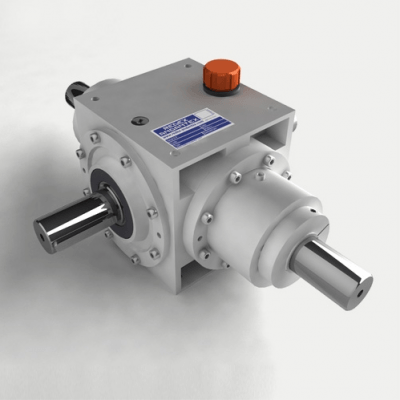

Right Angle Gearboxes

Redex offers an extensive range of right angle gearboxes to meet the quality, performance, and price requirements of each application. Anglgear, the original right angle drive, is readily available in ratios 1:1 and 2:1 with powers up to 10 HP. The Z-series is a modular design based on a cubic housing with spiral bevel gears and ratios from 0.5 to 6:1 reaching powers of 370 HP. The R-Series is the large range with powers up to 2500 HP. These standard components offer a designer a library of solutions for any right angle application.

Differentials

The SR Series differential design is based on a compound epicyclic gearing system offering a high torque capacity and a wide range of reduction ratios in a very compact space. The patented thermo-plastic injection process gives the exclusive opportunity to increase the quantity of planet trains, without increasing the unit’s size.

Mechanical Clutches

The BD unit consists of two jaw assemblies mounted on separate shafts, each supported by two bearings, and enclosed in rugged cast iron housings. This type of construction ensures fail-safe disengagement.

Reducers & Multipliers

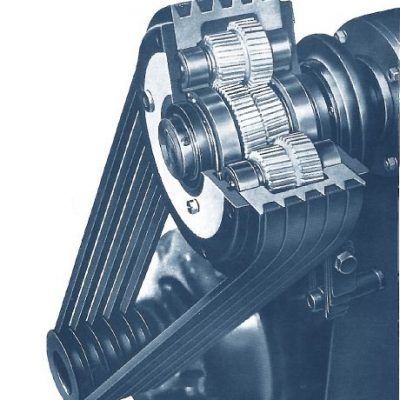

BVI Multi-speed Units are used for speed adjustment at constant power level. This range of heavy duty industrial multi-speed gearboxes are designed for continuous operation.

Magnetic Particle Brakes, Clutches & Torque Limiters

MEROBEL is a well-known solutions supplier for Converting, Printing, Packaging Industries, as well as for Automation / Material Handling, Wire and Cable, and Test rigs.

MEROBEL offers a wide portfolio of dedicated products: high technology mechatronic components such as ElectroMagnetic Particle Brakes & Clutches, Web Tension Controllers and Electronics, various sensors and transducers for force and torque control.

Whether you are looking for an electromagnetic braking system, a magnetic brake, a particle brake, electromagnetic powder brakes, clutches and torque limiters, electro-magentic clutches, or more, check out our line below!

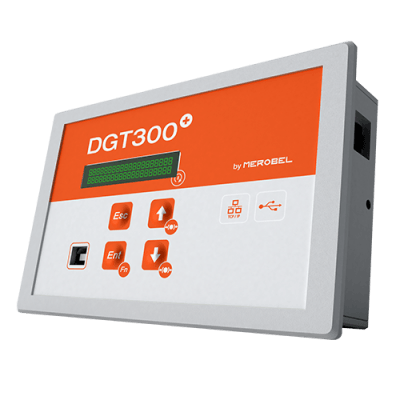

Electronics & Controllers

Merobel DIN rail mounting electronics for transducer amplification, current regulated power supplies and web tension controller.

Transducers & Sensors

The web tension transducers (which are a specialized type of load cells) are used as the force sensor feedback devices in web tension control and/or in tension display systems for continuous printing, converting, labeling or finishing process. MEROBEL load cells robust design allows to measure real time total web tension whatever the industrial environment with the highest accuracy and reliability, in order to dramatically reduce waste, web breakage or length change.